The Ultimate Guide to Custom Braided Hoses

Whether you're restoring a classic car, building a track bike, or upgrading a daily driver, chances are you've come across braided hoses - or at least heard people talk about them. But what drives enthusiasts to prefer custom braided hoses instead of regular rubber ones? And what makes these hoses a worthwhile upgrade?

This guide breaks it all down: what they are, why they're useful, and how they make a difference on the road (or track!).

What Are Custom Braided Hoses?

In simple terms, braided hoses are reinforced fluid lines. Most have either a PTFE or reinforced rubber inner core and a stainless steel braided outer layer for strength. Custom brake lines are commonly wrapped in a wipe-clean PVC coating for durability and protection.

Braided hoses are designed to handle pressure and heat, making them ideal for brake, clutch, oil, fuel, and coolant systems - especially in high-performance or modified vehicles.

The "custom" part means you can build them to the exact length, fitting type, and configuration you need. No struggling to make off-the-shelf parts fit. No messy loops or excess hose. No adapters cobbled together. No trying to assemble them yourself and wondering if you've done it right. Just the hoses you need, built to your exact specifications and delivered ready to fit.

Why Choose Custom Braided Hoses?

There are a few key reasons custom hoses are so popular:

-

Performance

Minimal hose expansion under pressure results in a more consistent flow.

-

Safety

Braided hoses are more durable and less likely to fail under harsh conditions.

-

Fitment

Whether you're routing lines through a tight engine bay or trying to avoid bulky parts, a made-to-measure hose reduces hassle.

-

Looks

Braided lines just look cleaner and more professional.

And importantly, you get to control how everything. Want to route your clutch line behind the intake manifold instead of around it? Need to avoid contact with a hot exhaust pipe or turbocharger? You can configure your hose to do exactly that.

Where Custom Braided Hoses Make a Real Difference

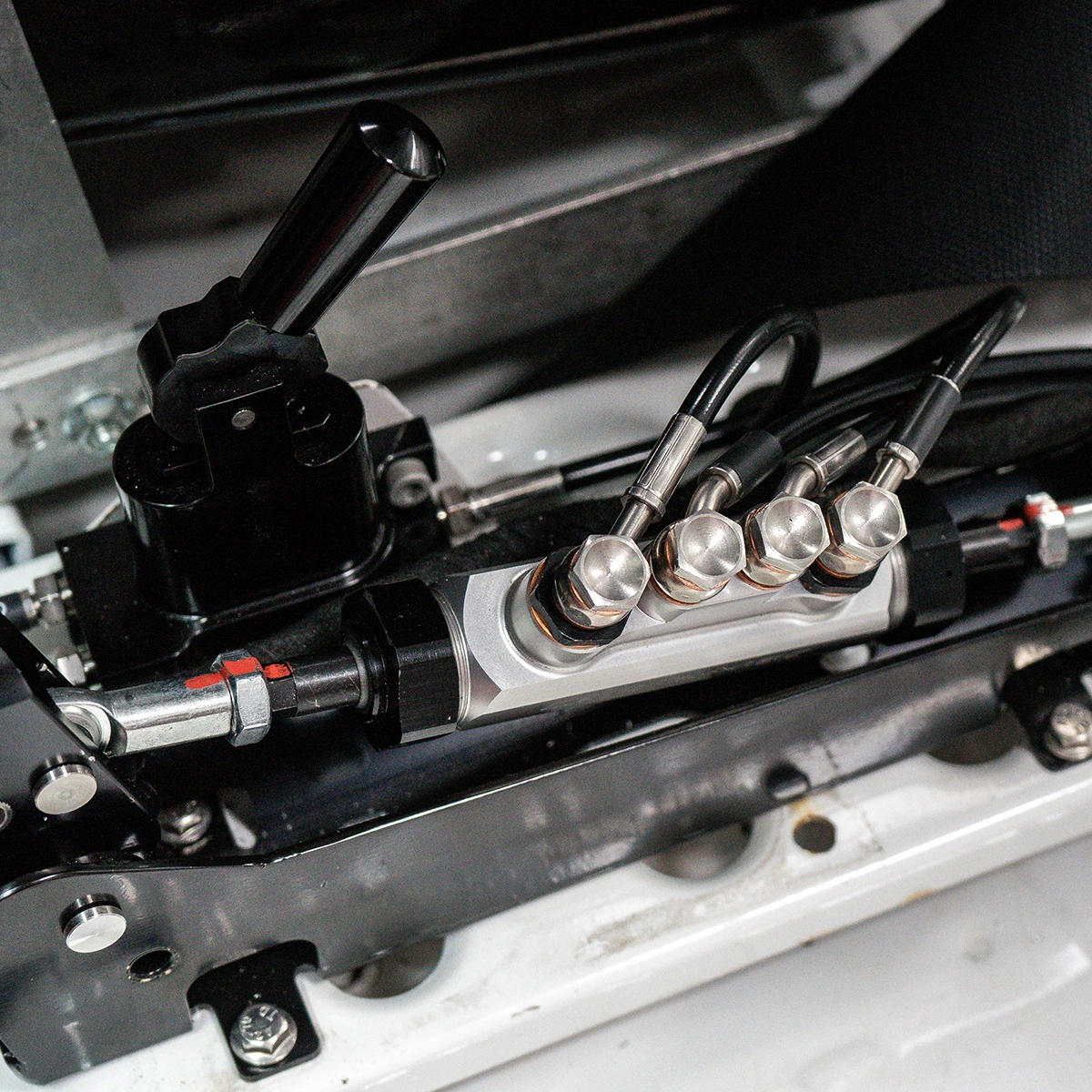

Brake and Clutch Lines

This is probably the most common use for custom braided hoses, especially in performance cars and motorcycles.

Rubber brake hoses can swell under pressure, especially as they age. You stomp on the pedal or grab the lever, and some of that braking force gets absorbed by the hose rather than being delivered directly to the calipers. This can lead to a soft, spongy, inconsistent feel. Stainless braided hoses help prevent that.

With custom brake hoses, you're also not limited to factory routing or lengths. This is ideal if:

-

You've installed aftermarket brake calipers or master cylinder

-

Your car has a big brake kit

-

You ride a custom motorcycle and want tidy routing

-

Your original brake lines are no longer available

-

You're converting from hardline to braided in a kit car or race build

The same applies to custom clutch lines. On hydraulic clutch setups, a firmer hose can result in an improved bite and feel, especially useful in motorsport or fast road driving where quick engagement matters.

And if you're working on a motorcycle, custom motorcycle brake lines make a big difference in both safety and aesthetics. You can avoid awkward routing or loops which aren't ideal.

Fuel, Oil & Coolant Systems

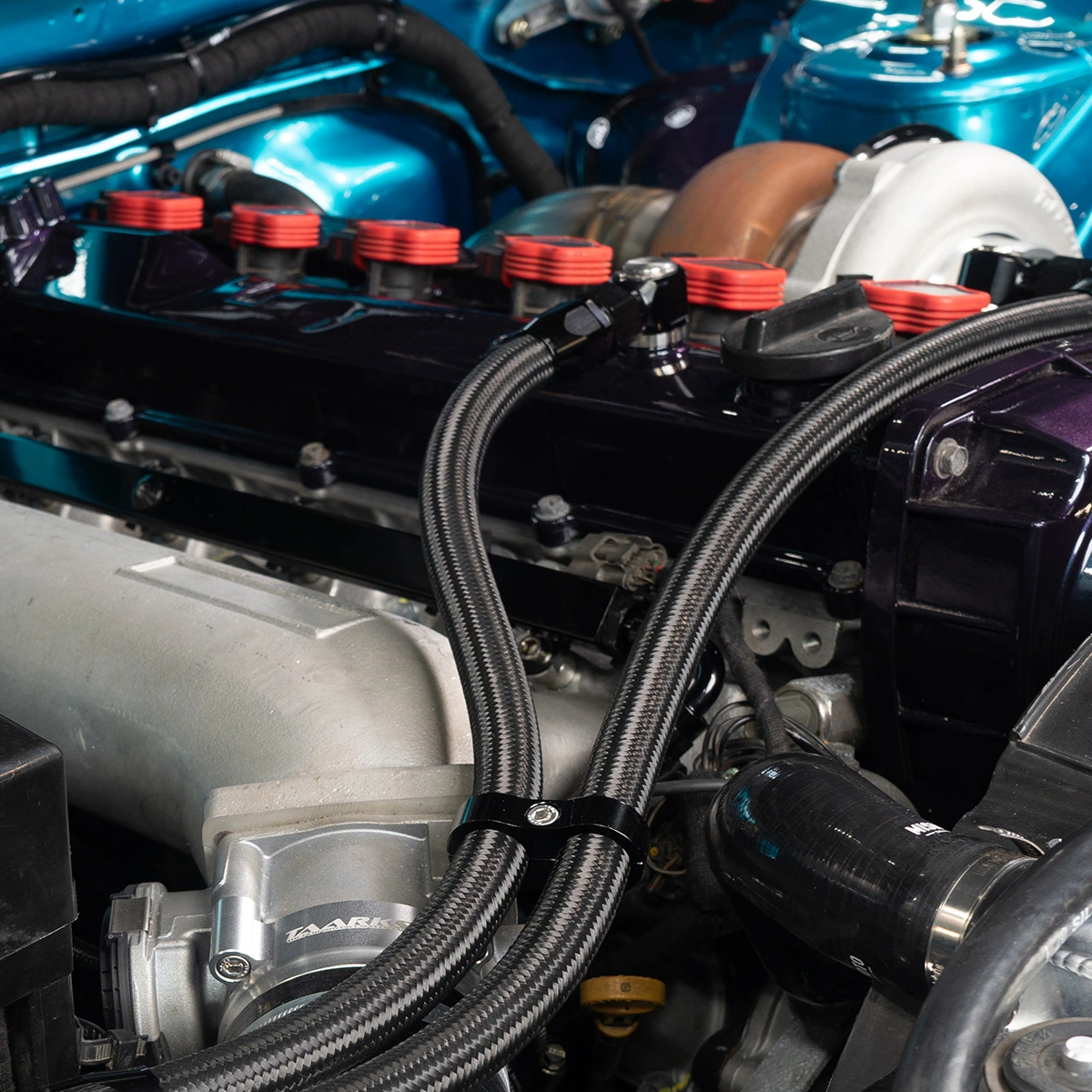

The engine bay is where braided hoses really shine.

In fuel systems, especially those running ethanol blends (like E85 or race fuel), PTFE braided lines won't degrade like rubber does. That means safer fuel delivery, no fuel vapour being released into the cabin, and long-term reliability. Being able to specify exact hose lengths and fittings can be the difference between a clean, reliable build and a frustrating one.

For oil cooler hoses, custom lengths mean you can mount the oil cooler where you want and still achieve clean, kink-free routing. The same applies to coolant lines on engine swaps or high-performance applications.

Custom hoses are also invaluable when using AN fittings (short for Army-Navy spec), which are common in motorsport and performance builds. Being able to choose from a range of hose sizes, fittings and adapters lets you match up hose ends cleanly with your fuel rail, oil cooler, catch can setup, or anything else that requires high-performance fluid transfer.

Custom Turbo Oil & Coolant Lines

Turbocharged engines run hot and fast. Between the high oil pressures feeding the turbo bearings and the heat soak from the exhaust manifold, it's one area where standard rubber hoses can often fail.

Custom turbo lines with a PTFE inner core and stainless steel braiding offer the durability and temperature resistance needed to cope with this environment. They are also far less prone to the kinds of leaks and pressure drops that can kill a turbo if left unchecked.

Having made-to-measure turbo oil and coolant lines can save hours of frustration. They let you route your hoses safely around hot components, avoid contact with sharp edges, and ensure your fittings connect securely and safely at both ends.

Custom turbo hoses are also handy for turbo conversions on naturally aspirated engines, where factory hoses don't exist. With a custom oil feed and return, you can ensure oil pressure is stable and flow rates are correct: the key to turbo longevity.

Paired with proper fittings, they make for a neat, reliable turbocharger system.

Braided Hose Specifications

Each hose size and type has its own operating pressure, temperature range, fluid compatibility, and other specifications. Here's what to expect from our braided hoses:

| AN3 PTFE Brake Lines | |

|---|---|

| Stainless Steel Braided | |

| Maximum Operating Pressure | 4206 PSI (290 BAR) |

| Burst Pressure | 12618 PSI (870 BAR) |

| Minimum Bend Radius | 19mm (0.7") |

| Outer Hose Material | Stainless Steel Braiding (coated in wipe-clean PVC) |

| Inner Hose Material | PTFE |

| Hose Bore Type | Smooth Bore |

| Inner Diameter (ID) | 3mm (1/8") |

| Outer Diameter (OD) | 8mm (5/16") |

| Hose Size | AN3 (-3 AN, Dash 3) |

| Fittings Material | Stainless Steel (303/304) |

| Operating Temperature Range | -70°C to 250°C (-94°F to 482°F) |

| Fluid Compatibility |

|

| Common Applications | Brake Lines, Clutch Lines |

| Hose Weight (Per Metre) | 71g (0.16lbs) |

| AN4 PTFE Hoses | |

|---|---|

| Stainless Steel Braided | |

| Maximum Operating Pressure | 3000 PSI (206.8 BAR) |

| Burst Pressure | 10000 PSI (689.5 BAR) |

| Minimum Bend Radius | 32mm (1.3") |

| Outer Hose Material | Stainless Steel Braided (coated in wipe-clean PVC, optional) |

| Inner Hose Material | PTFE |

| Hose Bore Type | Smooth Bore |

| Inner Diameter (ID) | 6mm (1/4") |

| Outer Diameter (OD) | 13mm (1/2") |

| Hose Size | AN4 (-4 AN, Dash 4) |

| Fittings Material | Stainless Steel (303/304) |

| Operating Temperature Range | -70°C to 250°C (-94°F to 482°F) |

| Fluid Compatibility |

|

| Common Applications | Turbo Oil Feeds, Turbo Oil Returns, Turbo Water Feeds, Turbo Water Returns, Pedal Box Hoses |

| Hose Weight (Per Metre) | 86g (0.19lbs) |

| AN6 Rubber Hoses | AN6 PTFE Hoses | |||

|---|---|---|---|---|

| Stainless Steel Braided | Black Nylon Cotton Braided | Stainless Steel Braided | Black Nylon Cotton Braided | |

| Maximum Operating Pressure | 1000 PSI (68.9 BAR) | 500 PSI (34.5 BAR) | 3000 PSI (206.8 BAR) | |

| Burst Pressure | 6000 PSI (413.7 BAR) | 2000 PSI (137.9 BAR) | 10000 PSI (689.5 BAR) | |

| Minimum Bend Radius | 38mm (1.5") | 35mm (1.4") | 45mm (1.8") | 40mm (1.6") |

| Outer Hose Material | Stainless Steel Braiding (303/304) | Black Nylon Cotton Braiding | Stainless Steel Braiding (303/304) | Black Nylon Cotton Braiding |

| Inner Hose Material | CPE Rubber (reinforced with an embedded stainless steel weave) | PTFE | ||

| Hose Bore Type | Smooth Bore | Smooth Bore | ||

| Inner Diameter (ID) | 8mm (5/16") | 8mm (5/16") | ||

| Outer Diameter (OD) | 14mm (9/16") | 11mm (7/16") | ||

| Hose and Fittings Size | AN6 (-6 AN, Dash 6) | AN6 (-6 AN, Dash 6) | ||

| Female Thread Size | 9/16"-18 UNF (approx. 13mm diameter) | 9/16"-18 UNF (approx. 13mm diameter) | ||

| Flare Type | JIC (37° Flare) | JIC (37° Flare) | ||

| Fittings Type | Double Swivel (Full Flow) | Double Swivel (Full Flow) | ||

| Fittings Material | Aluminium Alloy (6061-T6) | Aluminium Alloy (6061-T6) | ||

| Operating Temperature Range | -40°C to 150°C (-40°F to 302°F) | -70°C to 250°C (-94°F to 482°F) | ||

| Fluid Compatibility |

|

|

||

| Common Applications | Coolant Systems, Radiators, Oil Lines, Fuel Lines, Hydraulic Systems | Coolant Systems, Radiators, Oil Lines, Fuel Lines, Hydraulic Systems | ||

| Hose Weight (Per Metre) | 203g (0.45 lbs) | 156g (0.34 lbs) | 139g (0.31 lbs) | 151g (0.33 lbs) |

| AN8 Rubber Hoses | AN8 PTFE Hoses | |||

|---|---|---|---|---|

| Stainless Steel Braided | Black Nylon Cotton Braided | Stainless Steel Braided | Black Nylon Cotton Braided | |

| Maximum Operating Pressure | 1000 PSI (68.9 BAR) | 500 PSI (34.5 BAR) | 2500 PSI (172.3 BAR) | |

| Burst Pressure | 5000 PSI (344.7 BAR) | 2000 PSI (137.9 BAR) | 8000 PSI (551.5 BAR) | |

| Minimum Bend Radius | 40mm (1.6") | 35mm (1.4") | 60mm (2.4") | 55mm (2.2") |

| Outer Hose Material | Stainless Steel Braiding (303/304) | Black Nylon Cotton Braiding | Stainless Steel Braiding (303/304) | Black Nylon Cotton Braiding |

| Inner Hose Material | CPE Rubber (reinforced with an embedded stainless steel weave) | PTFE | ||

| Hose Bore Type | Smooth Bore | Smooth Bore | ||

| Inner Diameter (ID) | 11mm (7/16") | 11mm (7/16") | ||

| Outer Diameter (OD) | 17mm (11/16") | 14mm (9/16") | ||

| Hose and Fittings Size | AN8 (-8 AN, Dash 8) | AN8 (-8 AN, Dash 8) | ||

| Female Thread Size | 3/4"-16 UNF (approx. 17mm diameter) | 3/4"-16 UNF (approx. 17mm diameter) | ||

| Flare Type | JIC (37° Flare) | JIC (37° Flare) | ||

| Fittings Type | Double Swivel (Full Flow) | Double Swivel (Full Flow) | ||

| Fittings Material | Aluminium Alloy (6061-T6) | Aluminium Alloy (6061-T6) | ||

| Operating Temperature Range | -40°C to 150°C (-40°F to 302°F) | -70°C to 250°C (-94°F to 482°F) | ||

| Fluid Compatibility |

|

|

||

| Common Applications | Coolant Systems, Radiators, Oil Lines, Fuel Lines, Hydraulic Systems | Coolant Systems, Radiators, Oil Lines, Fuel Lines, Hydraulic Systems | ||

| Hose Weight (Per Metre) | 247g (0.55lbs) | 203g (0.45lbs) | 181g (0.40lbs) | 190g (0.42lbs) |

| AN10 Rubber Hoses | AN10 PTFE Hoses | |||

|---|---|---|---|---|

| Stainless Steel Braided | Black Nylon Cotton Braided | Stainless Steel Braided | Black Nylon Cotton Braided | |

| Maximum Operating Pressure | 1000 PSI (68.9 BAR) | 500 PSI (34.5 BAR) | 2000 PSI (137.9 BAR) | |

| Burst Pressure | 5000 PSI (344.7 BAR) | 2000 PSI (137.9 BAR) | 6000 PSI (413.7 BAR) | |

| Minimum Bend Radius | 55mm (2.2") | 45mm (1.8") | 65mm (2.6") | 60mm (2.4") |

| Outer Hose Material | Stainless Steel Braiding (303/304) | Black Nylon Cotton Braiding | Stainless Steel Braiding (303/304) | Black Nylon Cotton Braiding |

| Inner Hose Material | CPE Rubber (reinforced with an embedded stainless steel weave) | PTFE | ||

| Hose Bore Type | Smooth Bore | Smooth Bore | ||

| Inner Diameter (ID) | 14mm (9/16") | 13mm (1/2") | ||

| Outer Diameter (OD) | 21mm (7/8") | 16mm (5/8") | ||

| Hose and Fittings Size | AN10 (-10 AN, Dash 10) | AN10 (-10 AN, Dash 10) | ||

| Female Thread Size | 7/8"-14 UNF (approx. 20mm diameter) | 7/8"-14 UNF (approx. 20mm diameter) | ||

| Flare Type | JIC (37° Flare) | JIC (37° Flare) | ||

| Fittings Type | Double Swivel (Full Flow) | Double Swivel (Full Flow) | ||

| Fittings Material | Aluminium Alloy (6061-T6) | Aluminium Alloy (6061-T6) | ||

| Operating Temperature Range | -40°C to 150°C (-40°F to 302°F) | -70°C to 250°C (-94°F to 482°F) | ||

| Fluid Compatibility |

|

|

||

| Common Applications | Coolant Systems, Radiators, Oil Lines, Fuel Lines, Hydraulic Systems | Coolant Systems, Radiators, Oil Lines, Fuel Lines, Hydraulic Systems | ||

| AN12 Rubber Hoses | ||

|---|---|---|

| Stainless Steel Braided | Black Nylon Cotton Braided | |

| Maximum Operating Pressure | 1000 PSI (68.9 BAR) | 350 PSI (24.1 BAR) |

| Burst Pressure | 3750 PSI (258.6 BAR) | 1400 PSI (96.5 BAR) |

| Minimum Bend Radius | 75mm (3.0") | 65mm (2.6") |

| Outer Hose Material | Stainless Steel Braiding (303/304) | Black Nylon Cotton Braiding |

| Inner Hose Material | CPE Rubber (reinforced with an embedded stainless steel weave) | |

| Hose Bore Type | Smooth Bore | |

| Inner Diameter (ID) | 17mm (3/4") | |

| Outer Diameter (OD) | 24mm (61/64") | |

| Hose and Fittings Size | AN12 (-12 AN, Dash 12) | |

| Female Thread Size | 1-1/6"-12 UNF (approx. 25mm diameter) | |

| Flare Type | JIC (37° Flare) | |

| Fittings Type | Double Swivel (Full Flow) | |

| Fittings Material | Aluminium Alloy (6061-T6) | |

| Operating Temperature Range | -40°C to 150°C (-40°F to 302°F) | |

| Fluid Compatibility |

|

|

| Common Applications | Coolant Systems, Radiators, Oil Lines, Hydraulic Systems | |

| AN16 Rubber Hoses | ||

|---|---|---|

| Stainless Steel Braided | Black Nylon Cotton Braided | |

| Maximum Operating Pressure | 750 PSI (51.7 BAR) | 350 PSI (24.1 BAR) |

| Burst Pressure | 2500 PSI (172.4 BAR) | 1400 PSI (96.5 BAR) |

| Minimum Bend Radius | 110mm (4.4") | 95mm (3.7") |

| Outer Hose Material | Stainless Steel Braiding (303/304) | Black Nylon Cotton Braiding |

| Inner Hose Material | CPE Rubber (reinforced with an embedded stainless steel weave) | |

| Hose Bore Type | Smooth Bore | |

| Inner Diameter (ID) | 22mm (7/8") | |

| Outer Diameter (OD) | 31mm (1-7/32") | |

| Hose and Fittings Size | AN16 (-16 AN, Dash 16) | |

| Female Thread Size | 1-5/16"-12 UNF (approx. 31mm diameter) | |

| Flare Type | JIC (37° Flare) | |

| Fittings Type | Double Swivel (Full Flow) | |

| Fittings Material | Aluminium Alloy (6061-T6) | |

| Operating Temperature Range | -40°C to 150°C (-40°F to 302°F) | |

| Fluid Compatibility |

|

|

| Common Applications | Coolant Systems, Radiators, Oil Lines, Hydraulic Systems | |

| AN20 Rubber Hoses | ||

|---|---|---|

| Stainless Steel Braided | Black Nylon Cotton Braided | |

| Maximum Operating Pressure | 500 PSI (34.5 BAR) | 350 PSI (24.1 BAR) |

| Burst Pressure | 2000 PSI (137.9 BAR) | 1400 PSI (96.5 BAR) |

| Minimum Bend Radius | 128mm (5.0") | 115mm (4.5") |

| Outer Hose Material | Stainless Steel Braiding (303/304) | Black Nylon Cotton Braiding |

| Inner Hose Material | CPE Rubber (reinforced with an embedded stainless steel weave) | |

| Hose Bore Type | Smooth Bore | |

| Inner Diameter (ID) | 28mm (1-1/8") | |

| Outer Diameter (OD) | 36mm (1-13/32") | |

| Hose and Fittings Size | AN20 (-20 AN, Dash 20) | |

| Female Thread Size | 1-5/8"-12 UNF (approx. 39mm diameter) | |

| Flare Type | JIC (37° Flare) | |

| Fittings Type | Double Swivel (Full Flow) | |

| Fittings Material | Aluminium Alloy (6061-T6) | |

| Operating Temperature Range | -40°C to 150°C (-40°F to 302°F) | |

| Fluid Compatibility |

|

|

| Common Applications | Coolant Systems, Radiators, Oil Lines, Hydraulic Systems | |

How to Build the Right Hose for Your Project

If you're thinking of replacing tired, old hoses or building something custom, here's a quick guide to getting it right:

-

Know the application

Brake, clutch, oil, fuel, coolant, or something else?

-

Decide on material

PTFE (best for brake, clutch or race fuels) or reinforced rubber (more flexible, easier to route)?

-

Pick your size

AN3 is common for brake or clutch; AN4 for turbo, AN6, AN8, AN10, AN12 for oil/fuel/coolant and AN16 or AN20 for radiators.

-

Choose your fittings

Straight, angled, banjo, threaded – depends on what you're connecting to.

-

Measure carefully

Use string or flexible wire to test your intended routing first.

-

Avoid tight bends

All hoses have a minimum bend radius. Don't kink them.

-

Double check thread types

Metric, UNF, NPT - don't assume they're all the same.

Common Mistakes to Avoid

-

Avoid routing too close to hot components – use high-temperature heat sleeving if you can't avoid it.

-

Don't over-tighten hose ends - follow the correct torque specs.

-

Always test your hoses before going out on the road.

Custom Braided Hoses Not Just for Motorsport

They offer a practical and safe upgrade for almost any vehicle. From custom brake lines to fuel hoses made to order, having full control over your hose setup gives you confidence every time you turn the key. For upgrading a daily driver, building a drift car, or restoring a vintage motorcycle, custom hoses are a small detail that makes a big difference.

Want to build your own hoses? Shop our range of custom braided hoses now.

The minimum bend radius R is used to determine the tightest curve the hose can make without getting damaged or blocking the flow inside.