Custom Clutch Lines

Made To Measure Custom Stainless Steel Braided Clutch Lines

Upgrade your clutch system with our custom stainless steel braided clutch lines, engineered for precision, durability, and unrivaled performance.

Our custom clutch lines feature a high-performance PTFE core, which is wrapped in multiple layers of stainless steel braiding and finished with a wipe-clean PVC coating. This 3-layer hose design helps maintain a consistent clutch by reducing hose expansion under pressure. Whether you're on the road or heading to the track, our custom clutch lines will improve your braking.

Custom Clutch Line Benefits and Features

-

Increased Clutch Performance

Enjoy a sharper, more responsive clutch.

-

Got a Spongy Clutch?

Our braided clutch lines really do reduce the spongy feeling you feel with old and tired rubber clutch hoses. Soft rubber hoses tend to expand under pressure, so they often feel slow and sluggish to respond.

-

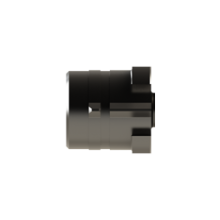

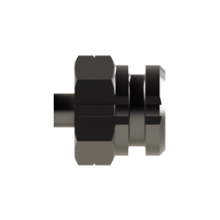

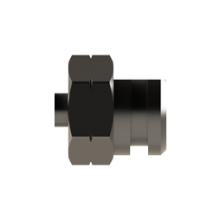

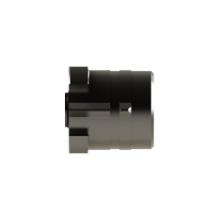

Stainless Steel Fittings

Designed for a lifetime of use, all our clutch hose fittings are machined in the UK from rust-resistant stainless steel. We will never use mild or zinc plated steel fittings.

-

Strong PTFE Core

The high-performance PTFE core ensures long-lasting and reliable clutch performance, even under extreme conditions. The core will not weaken or deteriorate with age. PTFE is one of the most chemically resistant materials known to man, providing much higher resistance to clutch fluid than traditional rubber hoses.

-

Stainless Steel Braiding

The durable PTFE core is reinforced with stainless steel braiding, which helps deliver consistent clutch pressure. This design reduces hose expansion, delivering dependable performance for life. Our stainless steel braiding has closely woven stainless steel strands, unlike many other brands that have a looser weave, which reduces the strength of the hose.

-

Wipe-clean PVC Coating

The final layer of the hose features a wipe-clean PVC coating, designed to protect the hose from road debris and water that could become trapped between the stainless steel braiding.

Custom Clutch Hoses

-

100% Made to Measure

Choose every part of your clutch hose: length, fitting types, fitting sizes, fitting angles and add a maximum of three supports or brackets.

-

Clutch Hose Colours

We have a wide range of hose colours, starting from a neutral black coating, to all colours of the rainbow. We also have a selection of transparent hose colours, which show off the shiny stainless steel weave underneath. Our custom clutch lines not only improve your clutch, they look the part too!

-

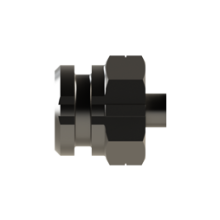

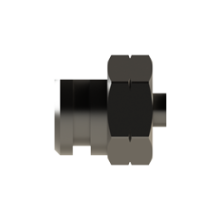

Convex or Concave Seats

On most swivel male and swivel female fittings you can choose from a dual seat, convex seat, or concave seat. The specially designed dual seat allows you to mate either a convex and concave fitting, ideal for when you're not sure which seat you need.

-

Easy Installation

Being pre-made to your exact specifications, fitting the hose is a breeze. No more rusty and corroded fittings, our precision-made stainless steel fittings are as smooth as silk.

We designed our custom stainless clutch lines to work with all types of vehicles and clutch fluids. Whether you drive a classic car or ride a modern motorcycle, our stainless steel braided clutch hoses really will make the difference.

Upgrade your clutch system with our reliable custom clutch hoses today. Start building your custom clutch lines now!

-

Do stainless steel clutch lines improve the clutch?

Our custom clutch lines have a strong PTFE core which is wrapped in multiple layers of stainless steel braiding. Then to finish, the stainless steel braid is coated in a durable, wipe-clean PVC coating. This 3-layer hose design greatly reduces expansion under pressure, ensuring consistent and precise clutch control.

Rubber clutch hoses get spongy and soft over time, so they can expand during hard clutch use, which often results in them feeling sluggish. Our stainless steel braided lines stay strong for a lifetime.

-

Are your custom clutch lines covered by a lifetime warranty?

Yes, our custom clutch lines include a lifetime warranty. This lifetime warranty covers any defects in materials or workmanship. You will not find a better hose warranty elsewhere.

-

Can I return or exchange my custom clutch line?

Yes, we offer a 100-day hassle-free returns policy for custom clutch lines. We know mistakes can happen and we want to make sure you are completely satisfied. However, please double-check your clutch hose before ordering to avoid any silly mistakes, it does cost us to replace them!

-

How to make custom clutch lines?

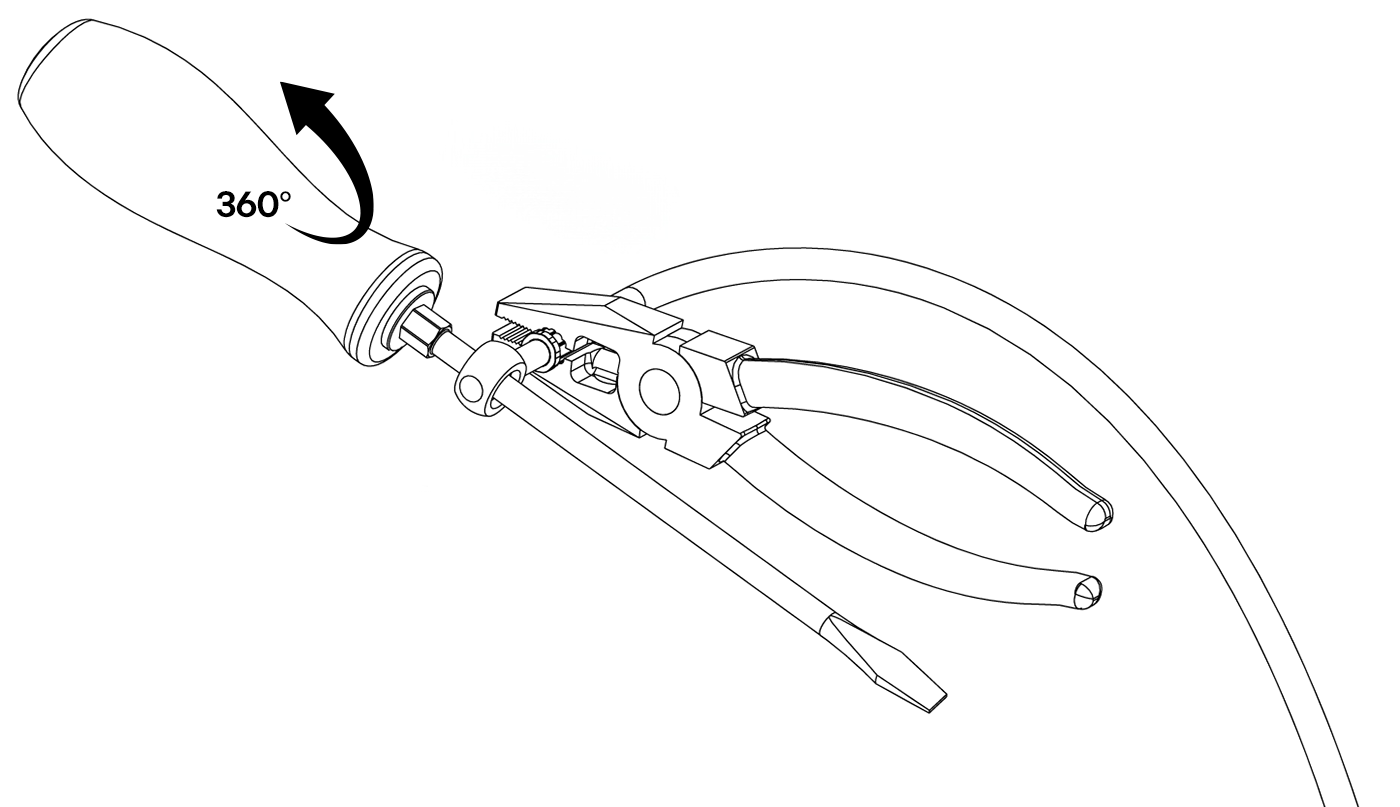

Our custom clutch hose builder makes designing your own hoses a breeze. Simply choose your hose fittings, followed by thread size and angle. Then choose your braided hose colour and add a maximum of three supports or brackets on each hose. Finally, choose your hose length and we'll start assembling your hoses as soon as we receive your order.

-

How do I measure custom clutch hoses?

The easiest way to measure your custom clutch hoses is with a piece of flexible wire or sturdy string. Make sure you go around all objects and follow all curves to make sure you don't measure the hose too tight, or the hose will be stretched when you fit it. You need to measure from the ends of male or female fittings and from the center hole of banjo fittings. Refer to the two vertical lines on the hose builder diagram when building your hoses.

When measuring motorcycle clutch hoses, make sure the wheel is off the ground so the suspension is fully extended.

-

Will these custom clutch hoses improve clutch pedal or clutch lever feel?

If you're replacing rubber clutch hoses for stainless braided, you will likely notice a big improvement in clutch pedal or clutch lever firmness and the clutch will be sharper. Perform a complete clutch fluid change at the same time for the biggest improvement.

-

Where are your stainless steel clutch fittings made?

Our stainless steel clutch fittings are made from scratch in the United Kingdom. The fittings are manufactured from high-quality raw stainless steel bar. By keeping production local, we can keep a close eye on quality control.

-

How are your clutch fittings attached to the hose?

We use an industrial swaging machine to crimp the fittings to the stainless steel hose. Once we've crimped the fittings to the hose, they won't be coming off! We've even seen a motorcycle crash where the only thing keeping the wheel attached to the motorbike were the hoses! We've seen other clutch lines that use reusable fittings, which aren't road legal in the UK.

-

Are your stainless steel braided clutch lines road legal?

Yes, our custom braided clutch lines are certified for use worldwide, meaning you can use them on any road around the globe. Please take a look at the certification section below, where you'll find a complete list of our global certifications and compliance standards.

-

How do I maintain and clean braided clutch lines?

Our custom clutch lines are made with rust-resistant stainless steel and are coated in a wipe-clean PVC coating, requiring minimal maintenance. To keep them in optimal condition, occasionally spray them with your favourite degreaser and wipe the hoses down with a clean cloth. Other than cleaning the hoses, they're virtually maintenance-free.

-

Are your custom clutch lines compatible with my vehicle?

Our custom clutch lines are compatible with all cars, motorcycles and commercial vehicles. If you need assistance when building your hoses, please contact us. We have a database containing specifications for over 10,000 cars and motorcycles. We also have 15+ years of experience in manufacturing braided clutch hoses, we've seen it all!

-

Are your custom braided clutch hoses suitable for track use?

Our custom clutch lines been tested and trusted at the highest levels of motorsport, including British Touring Cars, Drift Masters, British Superbikes and the Superbike World Championship.

-

Do your custom braided clutch lines come with any installation instructions or support?

We don't provide installation instructions as the clutch hoses are custom-made products, intended to be installed by a professional or competent person. If you run into any issues during installation, please contact us, and we'll be happy to offer advice.

-

Do I need to bleed my clutch after installing a braided clutch line?

Yes, when replacing a clutch line, whether it's stainless steel braided or rubber, you will always need to bleed the clutch system. We recommend making a complete clutch fluid change at the same time. Even with a bog standard DOT 3 or 4 fluid, you should notice a significant clutch improvement when fitting a stainless clutch line. Our custom braided clutch hoses are compatible with all clutch fluids.

-

How often should you replace a rubber clutch hose?

We recommend that you replace a rubber clutch hose every 5 years. Although, you should check regularly for any cracks, bulges or leaks as they might need replacing before then. When you replace a rubber clutch hose with our stainless steel hose, you shouldn't have to replace it ever again. However, we still recommend that you make regular checks on the custom clutch line like you would with any other vehicle component.

-

Why upgrade to custom stainless steel clutch lines?

If you're looking for a reliable upgrade to improve your clutch system, custom stainless steel clutch lines are an excellent, affordable choice. By replacing tired rubber hoses with high-quality stainless braided lines, you'll benefit from greater clutch consistency, durability, and enhanced clutch performance in all driving conditions.

-

Why don't stainless steel clutch lines come as standard on a vehicle?

Actually, when maximum clutch performance is needed, some performance cars and motorcycles do have stainless steel braided lines as standard. Most of the time, it's a cost-cutting exercise from the manufacturer when clutch performance isn't a huge issue. A brand new rubber clutch hose does the job for a while, but it wears down over time so it's a serviceable item, just like a clutch.

-

Why might I need a custom clutch line?

-

Master cylinder, slave cylinder or gearbox change

If you've modified, replaced or upgraded your master cylinder, slave cylinder, or gearbox, you might need a custom clutch line to ensure a proper fit.

-

Hard line replacement

When upgrading or replacing your clutch line, many people choose to replace the entire hard line with a flexible braided line. A new one-piece clutch line reduces the number of potential failure points and may also offer better routing. This conversion is commonly known as a full length master to slave clutch line.

-

Discontinued parts

For older vehicles, it's common for the manufacturer to discontinue clutch hoses which make them hard to find, and we definitely don't recommend buying used rubber hoses! Custom flexible clutch lines offer an ideal replacement, ensuring your vehicle remains roadworthy, and in most cases, our stainless hoses outperform the original rubber hoses in every single way.

-

Cheaper than rubber

Our custom braided clutch lines are often more cost-effective than traditional rubber hoses. With the added benefits of better performance and durability, this makes custom clutch lines the obvious choice.

-

Master cylinder, slave cylinder or gearbox change

-

What is AN3?

AN3 is a hose size that's most suited to clutch systems and the size we use for all our custom clutch lines. Compared with an original rubber clutch hose, you might be wondering why our hose has got a smaller external diameter, this is because we don't need overly thick rubber to keep hose expansion down. The high-performance PTFE core and stainless steel braiding on our custom clutch hoses do a much better job than rubber so the materials don't have to be as thick.

| Stainless Steel Braided | |

|---|---|

| Maximum Operating Pressure | 4206 PSI (290 BAR) |

| Burst Pressure | 12618 PSI (870 BAR) |

| Minimum Bend Radius | 19mm (0.7") |

| Outer Hose Material | Stainless Steel Braiding (coated in wipe-clean PVC) |

| Inner Hose Material | PTFE |

| Hose Bore Type | Smooth Bore |

| Inner Diameter (ID) | 3mm (1/8") |

| Outer Diameter (OD) | 8mm (5/16") |

| Hose Size | AN3 (-3 AN, Dash 3) |

| Fittings Material | Stainless Steel (303/304) |

| Operating Temperature Range | -70°C to 250°C (-94°F to 482°F) |

| Fluid Compatibility |

|

| Common Applications | Brake Lines, Clutch Lines |

| Hose Weight (Per Metre) | 71g (0.16lbs) |

The minimum bend radius R is used to determine the tightest curve the hose can make without getting damaged or blocking the flow inside.