Banjo Bolts

Shop premium banjo bolts — designed for racing, motorsport, and other high-performance applications. Select a banjo bolt to configure size and other options.

from£3.30

only£4.41

from£4.14

Banjo Bolts for Reliable Hydraulic Connections

Our range of banjo bolts are designed to provide secure, reliable fluid connections for your vehicle's hydraulic system. Whether you need stainless steel banjo bolts for your brake or clutch system, a double banjo bolt for dual connections, or a banjo bolt with a bleed nipple to make bleeding your system easier, we've got you covered. Available in a variety of sizes and materials, including stainless steel and lightweight aluminium, our banjo bolts are built for durability and performance. Whatever your setup, you'll find the right fit to keep your system running smoothly.

-

What is a banjo bolt, and how does it work?

A banjo bolt is a specialised fastener that connects banjo fittings to hydraulic components, allowing fluid to flow through its hollow body. Commonly used in brake, clutch, and turbo systems, it ensures a secure, leak-free connection. Their compact design makes it ideal for tight spaces like brake calipers.

-

What are the benefits of stainless steel banjo bolts?

Stainless steel banjo bolts offer superior corrosion resistance, making them ideal for long-term use in automotive, motorcycle, marine, and industrial applications. They offer high durability, precise fitment, and reliable performance under extreme pressure and harsh environments.

-

Are stainless steel banjo bolts better than zinc-plated or mild steel ones?

Yes. Stainless steel banjo bolts resist corrosion significantly better than zinc-plated or mild steel bolts, which can rust over time. This makes stainless steel the preferred choice for high-performance, marine, and long-term applications.

-

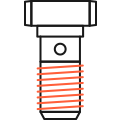

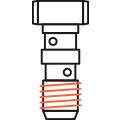

What is the difference between a single banjo bolt and a double banjo bolt?

Single banjo bolts are designed for use with a single banjo fitting, while double banjo bolts allow two banjo fittings to be connected with the same bolt. Single banjo bolts are commonly used in standard hydraulic connections, whereas double banjo bolts are often found in motorcycle brake systems, particularly for full-length race lines to each caliper.

Banjo bolts require washers to make a secure seal:

-

Single Banjo Bolts

Two washers (one on each side of the fitting).

-

Double Banjo Bolts

Three washers (one between each fitting and one on each outer side).

-

Single Banjo Bolts

-

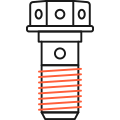

What are restricted banjo bolts, and when should I use one?

Restricted banjo bolts have a smaller internal passage to regulate fluid flow. They are commonly used in turbocharger oil feeds to prevent excessive oil pressure, which could lead to turbo seal failure. Restricted banjo bolts are essential for ball-bearing turbos that require controlled oil flow.

-

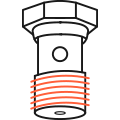

What is a banjo bolt with a bleed nipple used for?

Banjo bolts with a bleed nipple simplify the process of removing air from hydraulic systems. Banjo bleeder bolts are often used in brake systems to make bleeding easier, ensuring optimal brake performance.

-

How do I install a banjo bolt correctly?

To install a banjo bolt:

- Insert the banjo bolt through the eye of the banjo fitting.

- Use washers to create a seal (one on each side for single banjo bolts, or three for double banjo bolts).

- Ensure the washers are flat and seated properly.

- Tighten the bolt to the manufacturer's recommended torque setting.

- Avoid overtightening, as this can deform washers or damage threads, leading to leaks.

-

Why is my banjo bolt leaking, and how can I fix it?

Leaks can occur due to:

- Worn or improperly installed washers

- Incorrect torque settings

- Surface imperfections on the banjo fitting or bolt

- Damaged threads

To help fix the issue:

- Replace the washers with new ones.

- Check for surface irregularities.

- Ensure the banjo bolt is tightened correctly.

- Confirm that the washers sit flush against all surfaces.

-

Can I reuse copper crush washers when installing a banjo bolt?

No, copper crush washers should not be reused. They are designed to deform upon installation to form a proper seal, and reusing them may result in leaks. Always install new washers when replacing or reinstalling a banjo bolt.

-

Do I need thread sealant when installing a banjo bolt?

No, thread sealant is not required. Banjo bolts rely on the compression of washers to form a leak-proof seal. Applying sealant may interfere with proper sealing and is unnecessary.

-

How often should I replace my banjo bolts?

Banjo bolts typically do not require regular replacement unless they become damaged, corroded, or their threads are stripped. However, washers should always be replaced when servicing hydraulic components.

-

Do banjo bolts need to be aligned a certain way?

No, banjo bolts do not need to be aligned in a specific orientation. The banjo bolt design includes a ring with internal holes that allow fluid to flow in multiple directions, ensuring proper function regardless of alignment.

-

What are banjo screws?

Banjo screws are another name for the more commonly used term banjo bolt.

-

What are the most common sizes for brake banjo bolts?

The most common brake banjo bolts are AN3 banjo bolts, AN4 banjo bolts, M10 banjo bolts and M12 banjo bolts.

Looking for the right banjo bolt? Check out our range of: